Introduction

An infusion pump is a medical device which is used to deliver a large or small amount of fluid to the patient’s circulatory system with or without nutrients or medications in a controlled format. It is commonly used intravenously. There are several infusions which are used intermittently such as subcutaneous, epidural and arterial infusions. Commonly used infusion pumps are intended for some specialized purposes as follows:

- Enteral pump - The pump is used to deliver liquid nutrients and medication to the patient's digestive system.

- Patient-controlled analgesia (PCA) pump - A pump used to deliver pain medications, which is equipped with a feature that allows patients to self-administer a controlled amount of medication as needed.

- Insulin pump - A pump is often used to deliver insulin to patients with diabetes. Insulin pumps are often used at home.

What is Injection & What is Infusion

An injection is a procedure of placing a liquid, mainly a drug, into the patient’s body by using a needle (generally a hypodermic needle) and also a syringe. This is a technique for delivering drugs by the parenteral administration, which is, the administration through a route other than via the digestive tract. This parenteral injection including following injections such as:

- Subcutaneous injection

- Intramuscular injection

- Intravenous injection

- Intraperitoneal injection

- Intraosseous injection

- Intracardiac injection

- Intraarticular injection

- Intracavernous injection

The following figure shows the four types of angles of the needle insertion for the following four types of injections:-

- Intramuscular injection

- Subcutaneous injection

- Intravenous injection

- Intradermal injection

|

Figure – Angles of needle insertion |

Infusion is suffusing/ infusing of liquid substances directly into a vein using an infusion pump. These infusions are administered intravenously including in the designation of the speciality of drugs. Infusion also time controlled. It is normally referred to as a drip and many systems of the administration utilize a drip chamber, which prevents the air from entering the bloodstream (air embolism), and it allows an evaluation of the flow rate.

Comparison with the other routes of the administration, and to deliver medications and fluids throughout the body, the intravenous route is the fastest way. The bioavailability of the medication is 100% in IV therapy.

Infusion is used to deliver to the patient following things:-

- Blood

- Electrolytes

- Water

- Drugs

- Nutrients

- Other fluids

|

| Figure – Infusion of medication with the infusion IV set |

Differences (Comparison between Injection and Infusion)

There are some comparisons:-

- An injection doesn’t require any IV lines, nor does it require an IV pump.

- Injections are an effective way to administer medication.

- Infusions are much more similar to traditional IV drips.

- An infusion is typically used to treat some type of chronic issue such as pain.

- Infusion is well time controlled and able to deliver the medication in a period of time.

What is Intravenous (IV) Therapy?

Intravenous (IV) therapy is a therapy in which fluids are released directly into a vein. The intravenous route of administration can be used for both injections using a syringe at higher pressures; and for infusions, using only the pressure provided by gravity. Intravenous infusions are commonly known as drops.

The intravenous line is the fastest way to administer medications and replace fluids throughout the body because they are introduced directly into the circulation. Intravenous therapy can be used to replace fluid volume, correct electrolyte imbalance, for the medication manager, and for blood transfusions.

|

| Figure – Intravenous IV therapy |

What is Infusion Therapy

An exceptional to oral therapy is the infusion therapy: administration of injection with an antiseptic catheter. Traditionally, this technique has only been used inside the hospitals, but also infusion therapy is possible to be performed by specialist nurses in outpatient clinics or even at home by the present. These nurses are licensed by the State Pharmaceutical Board and meet authoritarian standards and the regulations which are set by the Board of Directors and government.

|

| Figure – Infusion therapy. |

What Does Infusion Therapy Treat?

The infusion therapy is generally used to take care of severe or any chronic infections which do not retort to oral antibiotics. Cancer and the cancer pain; Gastrointestinal diseases; Dehydration from vomiting, nausea, and diarrhoea. And the other serious illnesses like Crohn's disease is common. Other complex diseases that retort better to intestinal disorders including multiple sclerosis, certain arthritis, cardiovascular disease, and certain immune responses. Some cognitive disorders also require rashes.

Why we need infusion therapy

We need this, to not just oral medications when people who are seriously ill sometimes can't eat. Also, some actions cannot be taken orally, for the reason that stomach acids kill them and are no longer valuable & effective in treating your disease.

Examples/Types of infusion therapies

• Anti-Coagulation Therapy

• Blood Component Stimulating Factor

• Chemotherapy

• Hydration

• Anti-Hemophilic Factors

• Anti-Emetics

• Enteral Nutrition

• Pain Management

• Total Parenteral Nutrition

• Inotropic Therapy

History

The first attempt of intravenous medicine has been recorded in 1492. And it was invented the very first IV infusion pump device by Christopher Wren who was a famous architect in 1658. Then after seven years in 1665, it was carried out the first successful blood transfusion. During the intravenous procedures, it was invented the infusion pump prototypes controlling the flow rate in the 19th century.

It was able to see the huge advances of infusion pumps in the 20th century.

- Dean Kamen was able to do some major developments of the infusion pump in the 1970s’.

Types of the Infusion pump

There are three types of the infusion pumps according to IEC 60601-2-24 international standard as follows.

|

| Figure – Types of infusion pumps |

1. Volumetric:-

With infusion pumps (volumetric), the mechanical trigger sources the fluid in the tubing to move through a peristaltic effect that allows medication and nutrients or foods to be distributed. This mechanism could be categorized as rotating or linear.

The mechanism of rotary is made of the main rotor and entire with rollers that pressing the tube.

|

| Figure - Rotary peristaltic pump |

The linear mechanism is the most common type and consists of several independent fingers pressing sinusoidal on the silicon tube and these fingers perform the peristaltic movement and force the river to pass by pressing infusion line in opposition to the orifice of the device.

|

| Figure - Linear peristaltic mechanism |

This mechanism is stimulated by a stepper motor with reduction gear and also managed by an electronic circuit that shows on the screen the stream and also the amount of liquid to be identified delivered most linear and rotating infusion pumps (volumetric) have the drop sensor, an inline air sensor and occlusion pressure sensors.

|

| Figure - Several types of volumetric infusion pumps. |

Infusion pumps aspired at enteric nourishment have a mechanism identical to that of as described above. However, they are simple and haven’t any drop sensors and manage an uttermost pressure sensor.

2. Infusion Pumps with a Syringe:-

The pump system consists of an exterior electronic pump, an infusion of the line and syringe are companionable with this system and are generally disposable. The companionable syringe is a device that meets the specifications and requirements specified in recommendations of the manufacturer's.

|

| Figure – Pump system of the syringe. |

A disposable syringe is inserted into the pump for holding it, packed with a prescribed medicine fluid. Then this piston is mounted on a support and this equipment is programmed. It is sprayed manually or automatically. The injection pump automatically adjusts to the syringe connected to the equipment.

|

| Figure – Syringe infusion mechanism |

Syringe pumps are able to be used independently or else in a multi-channel system. There are two types of configurations for multichannel systems, such as two or more individual pumps which are programmed from a general control panel, and separate module controlling two or more individual pumps which are connected to the side of the system.

|

| Figure – Examples of syringe pumps |

Elastomeric infusion pumps are usually used for pain relief, in the stack or in the hospitals. In these kinds of pumps, the infusion pressure is gained by filling or satisfying the elastic balloon and also the flow control is done by the pressure disparity produced by the body temperature.

Main Parameters:-

Infusion pump has four major parameters such as volume, flow, time, and pressure.

The intention of the parameter of the volume is to evaluate the virtual values related to the volume applied. The volume to be administered should be based on the total amount of liquid available in the reservoir and it is recommended that it be between 0.1 ml and 0.1 ml 9999.0 ml. The delivery volume is that of the pump at the closing stages of the administration and it is not programmable. Corresponding to the total amount of used fluid.

The infusion time is the time interval in that the liquid is administered. The parameter can be programmed relevant to the respective requirements, such as Medicine administration. The pumps are programmable in seconds, minutes and hours.

The parameter related to the flow is the volume of liquid administered over a long period of time.

Time although most infusion pumps are delivered in millilitres per hour (ml / h). Volume flow: some can be programmed to provide mass in milligrams per hour (mg / h). Fluid The flow control can be volumetric or non-volumetric and the programming of the standards should be restricted to the measurement range of the instrument. In terms of flow, it is essential to mention that the bolus parameter, which is to supply a convinced amount of liquid in a short period of time.

Evaluation of the parameter applied to the pressure of the infusion pump, especially when monitoring the supply pressure that can be generated by the pump when there is a liquid lock in the system.

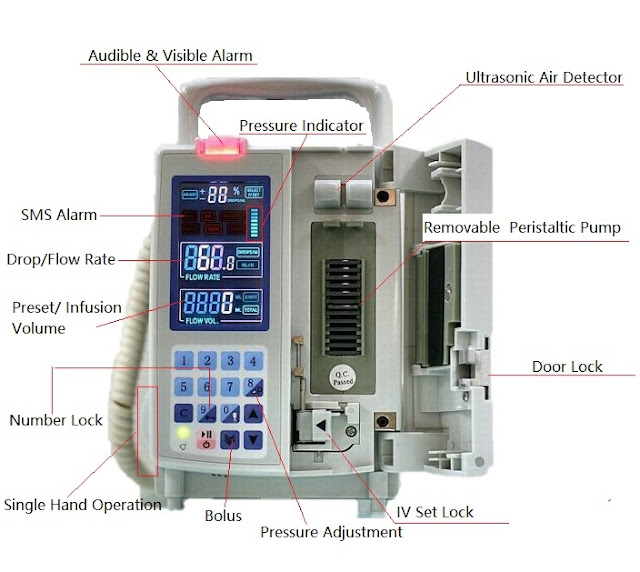

Main Components:-

There are the following components of the infusion pump.

1. Alarm

2. Control circuit

3. Infusion line & accessories

4. Infusion mechanisms

5. Display and control panel

6. Motor

7. Drop sensor in peristaltic pump

8. Air sensor inside the peristaltic pumps

9. Occlusion pressure sensor

10. Keypad

|

| Figure – Components of the infusion pump |

The following table illustrates the function of the above mentioned each and every component of the device.

|

Figure

– Table of the function of the components |

Accessories of the Device

There are accessories of the infusion pump which are important in deliver fluids as follows:-

1. Lines / Extensions.

These extensions also known as IV tubes are in different dimensions of lengths & diameters. These lines are unidirectional extensions and consists of valves in order to prevent from returning.

2. Needle.

This needle is used to guarantee & puncture the admittance

to the blood vessels.

3. Catheter.

4. Valve.

5. Filter

Filters can be antibacterial. Its function is to remove waste, prevent contamination, and prevent air bubbles from reaching the patient. To perform these tasks effectively, it is recommended to use the filter once in a clinical setting.

Working Principle

These pumps are controlled by a microprocessor. Peristaltic pumps sequentially compress and release the infusion tube, which injects fluid into the patient's catheter. The speed of a stepper motor determines the cycle speed of the peristaltic mechanism that controls the infusion rate. These pumps offer a flow rate of 0.01 to 999 ml/hour. Syringe-based pumps use a syringe as a reservoir for the drug that drives the liquid, pushing the plunger into the body of the syringe. A lead-screw mechanism presses a thread block against the piston. Spray regulators use spring or gas mechanisms to provide relative care constant force on the piston, which creates constant pressure for the fluid supply.

Operating Steps

- Patient’s skin should be cleaned by using alcohol and then the infusion site is fixed with the catheter port that is connected to the infusion pump.

- An appropriate solution fills inside the reservoir.

- It has been programmed to deliver/send a specific quantity of volume at a specific rate.

How It Works….

- Attach the IV tube to the saline bottle and fix an IV tube in the peristaltic sheet, then close the door of the pump

- Tap the switch which is situated behind equipment & start the machine.

- According to the requirement set the mode as adult or pediatric.

- Set the mode button of the unit of the volume.

- Depend on the several models of infusion pump you can then set as the next step, by setting the specific volume in specific time to be automatically calculated the rate and display on the screen and or can set directly set the rate.

- After finishing all these settings press the start button to start infusing the medication liquid.

- For infusing liquid at fast you can use the ‘BOLUS’ option. (BOLUS option - Clinically, the bolus is the administration of many drugs, drugs, or other drugs over a long period of time, usually for 1 to 30 minutes, to increase blood pressure in the blood.

- When you need to stop infusing medication you can press the STOP button.

Block Diagram of the Infusion Pump

|

| Figure – Block diagram of the infusion pump |

This diagram provides a scalable platform which integrates all the required circuitry to provide a configurable Infusion Pump in a single chip, including the followings:

- The high precision Analog front end, including a 0.1% accurate Voltage reference and up to 20 bits of resolution

- Circuitry for controlling the Relay Valve for controlling the flow rate and flow uniformity

- LCD direct-drive and control

- Power management capabilities including Battery Charging and Protection, Fuel Gauge, and Voltage Sequencing / Monitoring.

- On-chip EEPROM

Maintenance of the Device.

- To reduce and eliminate errors, maintenance takes everyone into account, the preventive and corrective measures essential for the proper functioning of the equipment and all their components. An object is understood to mean "every element, every part, apparatus, subsystem, instrument, functional unit or system that can be viewed separately.

- In this perspective, the inspection, clean-up and the replacement of each part are used and is relevant in the context of best practices. Conversely in order to determine the appropriate maintenance frequency for each and every infusion pump, and the following also should always be taken into account: the recommendations of the manufacturer, and the utilization of the device. Visual inspection and cleaning requirements must and should be performed daily.

- This is important regardless of the basic principles emphasize that preventive maintenance work must correspond to the measures and the specifications described by the device manufacturer are intended to prevent this. An error occurs that increases the average time between them. In this way, it is possible to guarantee maximum consistency and operational availability. Under the conscientiousness of the owner of the equipment plans are also preventative maintenance and if necessary, the components must be replaced during maintenance.

- The visual inspection consists of an evaluation of the general conditions of the infusion pump, that is the inspection of the casing, the piston, drop sensor, power cable, the keyboard, power cable, the battery, doors, and hinges. In addition, the operational status of the alarms is verified, not only the audio that will be heard but also the visual part of the illuminated signal LED.

|

| Figure - Visual inspection of an infusion pump (volumetric): lateral verification (on the left); Frontal (in the centre) and verification of the drop sensor (on the right). |

|

Figure - Visual inspection of an infusion pump (volumetric): exterior and interior door (on the left) and drop cable sensor (on the right). |

Good Practices

The manufacturer's safety instructions and instructions in the appropriate regulations must be followed to utilize the infusion pump safely. It is significant to note that internationally, there are numerous documented security incidents consisting of patients related to the use of this type of equipment. Mainly due to human error or defective equipment/consumables/accessories

The followings show the considerable good practices of uses:

Safety of the Instrument

- Assuring the preventive maintenance.

- Identifying the equipment has been attached to a label which shows the resistant for decontamination.

- Identifying the equipment states of the maintenance also the calibration

- Decontamination of the equipment according to the manufacturer’s guidelines.

- Prevention of the risk of the explosion, by not using any the flammable products near to the equipment.

Safe Handling

- Transportation of the equipment safely with sustain devices consists of wheels.

- Install the device in place and store it in a safe place so that it does not hit the patient if it falls.

- Use consumables/ accessories which are similar in temperament with the equipment.

- Avoid, the admittance to the arrangement of commands of the equipment, of avoiding risks of handling by the non-authorized persons.

- Avoiding of use of the pump in the battery mode and option to electrical extensions

- Minimizing the errors of handling consumables for standardizing the use of the equipment.

Storage

- Avoid the equipment from humidity and store it at a safe place.

- To charge the batteries of the equipment, make sure there are sufficient electrical outlets to be connected.

Technical Aspects to be Considered

- It is recommended to use syringes with a rigid volume and a reduced volume also shorter lines with the smaller inner diameters to minimize the effect of delayed liquid dosing, especially at flow rates of less than 2 ml / h.

- At very low flow rates (e.g. 0.5 ml/hr), normally used in the neonatology, and the conditions of utilizing should be parallel to those specified for calibration procedures to ensure that instrument error is reproducible under conditions. liquid viscosity and pressure.

- When utilizing multiple syringes on the same line, the effect of dead volume on the variation of the programmed flow of each syringe must be taken into account. This interaction between different pump infusions can lead to variation in doping error. Therefore, devices must be used to reduce the dead volume and reduce the reaction time of pumps.

Safety of the Instrument

- Assuring the preventive maintenance, also the functions that guarantee the relevant Metrological traceability;

- Identifying the instrument with a label which is opposing to the decontamination;

- Identifying the instrument’s state of the maintenance and the calibration;

- Decontaminating the instrument according to the instruction of the manufacturer;

- Preventing the risk of the detonation, by not using the instrument in a flammable environment.

Safe Handling

- Transporting the equipment securely with supportive devices which have wheels;

- Fixing the instrument in use, protecting it in a safe place so it will not strike the patient in case it falls;

- Using the consumables which are companionable with the instrument, in conformity with the specifications of the manufacturer. Normally, syringes which are different from the ones recommended by the manufacturer have a different internal diameter to the one programmed in the pump. This can lead to a significant error in the dosage of the fluids.

- The case presented in the Best Practice Guide exemplifies this situation (Lucas et al., 2015): a variation of 5 % in the diameter of the syringe can result in a flow error above 10%

- During the installation of the IV infusion set, verify if the referred and programmed dimensions in the pump are satisfactory;

- Block, if possible, the access to the configuration commands of the equipment, in case there is the risk of it being handled by non-authorised people (for example children or confused patients);

- Avoid using the infusion pump in battery mode and resorting to electrical extensions;

- In order to standardise the use of the instruments, they should be of the same model. In this manner, the errors in handling and in the utilisation of consumables are minimised;

- Place the configurations and the total amount of records to zero or to default values after using the devices/equipment as well as before its storage.

Infusion Pump Errors

Software problems:

If a software error message is shown, circumstances that the pump is inoperable at the moment. This happens in the absence of an identifiable problem.

Battery failures:

- A design concern causes overheating of the battery and the leads to premature battery failure.

- The battery is not replaced during the recommended according to the manufacturer’s guidelines to end of life routine maintenance.

Alarm errors:

- If there is a critical problem in the infusion pump such as occlusion (Clamped tubing) or else, presence of air in the infusion tube, the alarm alert fails to provide.

- Sometimes the device generates an occlusion alarm when the absence of an occlusion.

- Different alarm alerts of the infusion pump

|

Table – Different alarm alerts of the device |

Broken components:

The device might have been damaged during the utilize, which may result in an over-infusion or an under-infusion if the pump keeps on being used without being repaired.

Fire or sparks:

- The user plugs in or unplugs the equipment from an electrical outlet and obtains a spark.

- According to the following figures may be noted a burning smell or flames on the infusion pump.

Troubleshooting

👉 Watch Our YouTube Video on Infusion Concepts below (Part 1):-

👉 Watch Our YouTube Video on Infusion Pump below (Part 2):-

References

- Alexander, M., Corrigan, A., Gorski, et. al. (2010). Infusion Nursing: An Evidence-based Approach. 3rdEdition. Saunders Elsevier.

- Association for the Advancement of Medical Instrumentation (AAMI) & US Food and Drug Administration (FDA). 2010. Infusing Patients Safely Priority Issues From the AAMI/FDA Infusion Device Summit. URL:http://s3.amazonaws.com/rdcmsaami/files/production/public/FileDownloads/Summits/A

- AMI_FDA_Summit_Report.pdf. Consultado em 2016-10-16. BATISTA, E., BISSIG, H., PETTER, H., et al. (2015). Primary standards for measuring flow rates from 100 nl/min to 1 ml/min – gravimetric principle. Biomedical Engineering, de Gruyter, 60:4.

- ISO 3696:1978. Water for analytical laboratory use -- Specification and test methods.

- Timmerman, A., Snijder, R., Lucas, P. et al. (2015). How physical infusion system parameters cause clinically relevant dose deviations after set point changes. Biomedical Engineering, de Gruyter, 60:4.

- Lewin, Ch. (2016). Precision Fluid Handling. Performance Motion Devices. URL: https://www.pmdcorp.com/resources/case_studies/4#. Consulted on 2017-03-30

Article Prepared By:-

I was diagnosed as HEPATITIS B carrier in 2013 with fibrosis of the

ReplyDeleteliver already present. I started on antiviral medications which

reduced the viral load initially. After a couple of years the virus

became resistant. I started on HEPATITIS B Herbal treatment from

ULTIMATE LIFE CLINIC (www.ultimatelifeclinic.com) in March, 2020. Their

treatment totally reversed the virus. I did another blood test after

the 6 months long treatment and tested negative to the virus. Amazing

treatment! This treatment is a breakthrough for all HBV carriers.

This comment has been removed by the author.

ReplyDeleteThe best Article that I have never seen before with useful content and very informative.Thanks for sharing the info.

ReplyDeleteCoachella IV Drips El Centro CA

Zabdi Resources, LLC is an online distributor of scientific products, safety products, medical products and environmental products in affordably priced.

ReplyDelete